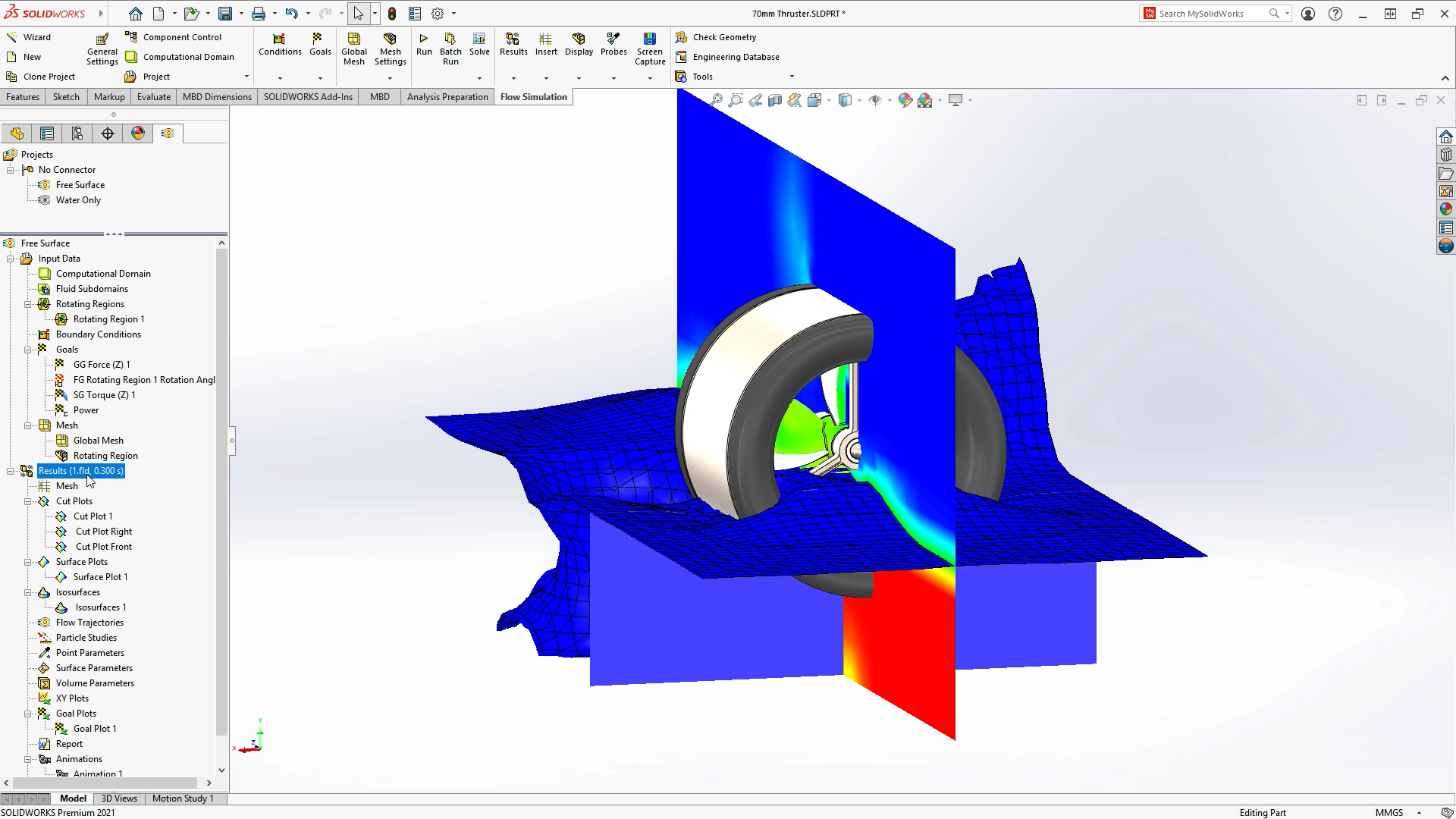

For the boundary representation, the Immersed Boundary (IB) approach, which does not require a boundary-conforming mesh, is used.

Comparative calculations on different mesh types illustrates that the best simulation precision, characterized by minimum Local Truncation Error (LTE), is obtained on Cartesian meshes. Detailed explanation and examples will support how this choice of mesh generation algorithm enables SolidWorks Flow Simulation to offer a best-in-class CFD solution centered upon simplicity, speed, and robustness.ĪBSTRACT For the numerical simulation of Navier-Stokes equations, the choice of the mesh type plays a significant role. This paper details the approach and theory behind the Cartesian mesh generation used in SolidWorks Flow Simulation. Solidworks trainig and project blog : phone: +989124780268 (Whats app - Telegram - IMO)ADVANCED BOUNDARY CARTESIAN MESHING TECHNOLOGY IN SOLIDWORKS FLOW SIMULATION Overview SolidWorks® Flow Simulation is an intelligent, easy-to-use computational fluid dynamics (CFD) program that facilitates the work of design engineers who use SolidWorks 3D CAD software for design creation.

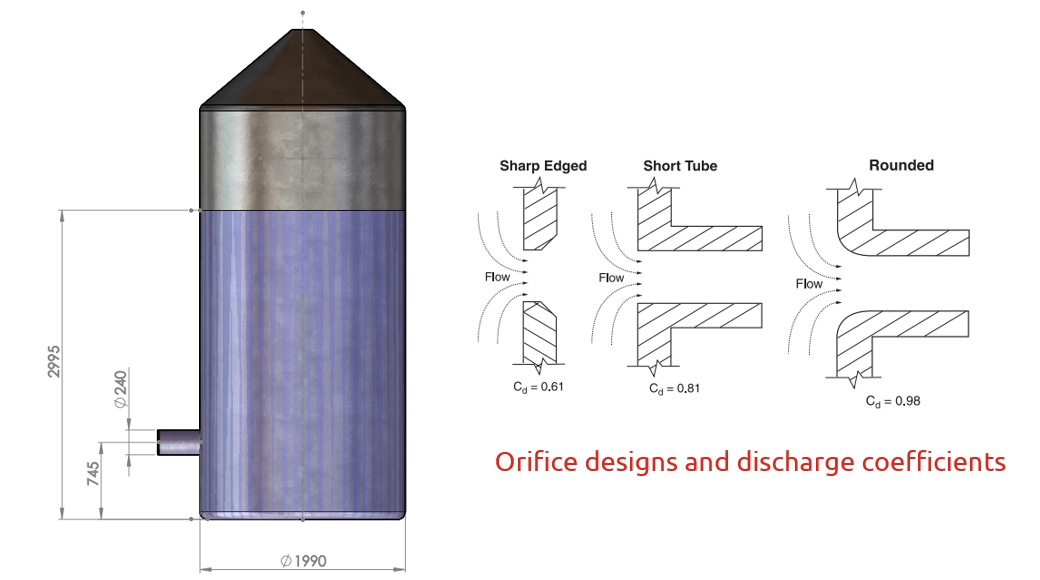

Wave effect on offshore sea platform in Solidworks by ARACo We can handle free_surface flow modeling and simulation with best quality in Solidworks.įree-surface simulation - watercourse - by ARACo Therefore, special methods are developed for the computation of free surface flows.

Conventional methods of computation are insufficient for such analysis. Computation of free surfaces is complex because of the continuous change in the location of the boundary layer. This can be the boundary between two homogeneous fluids, like water in an open container and the air in the Earth's atmosphere that form a boundary at the open face of the container. In physics, a free surface flow is the surface of a fluid flowing that is subjected to both zero perpendicular normal stress and parallel shear stress.

0 kommentar(er)

0 kommentar(er)